M

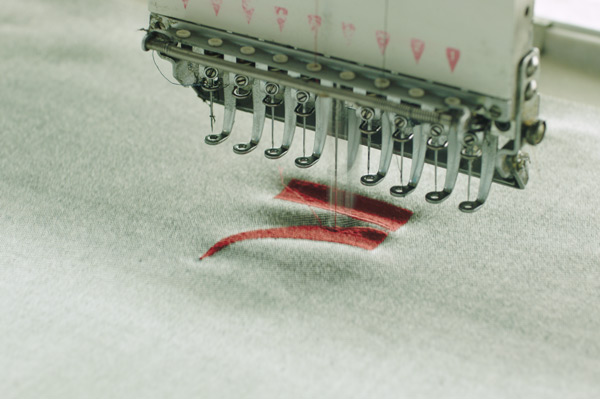

anufacturingAt T&C, our manufacturing process is comprised of cutting, sewing, laundry, and finishing & packing. Our manufacturing processes are overseen with inline inspection by our Quality Assurance Department, ensuring the highest standards at each step of the production cycle.

cutting

SEWING

LAUNDRY